|

|

||||||||||||||||

|

|

|

|

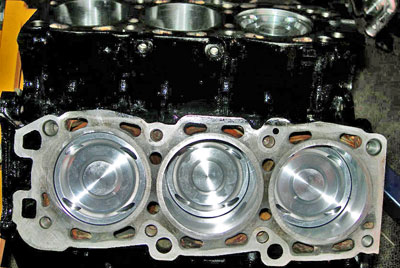

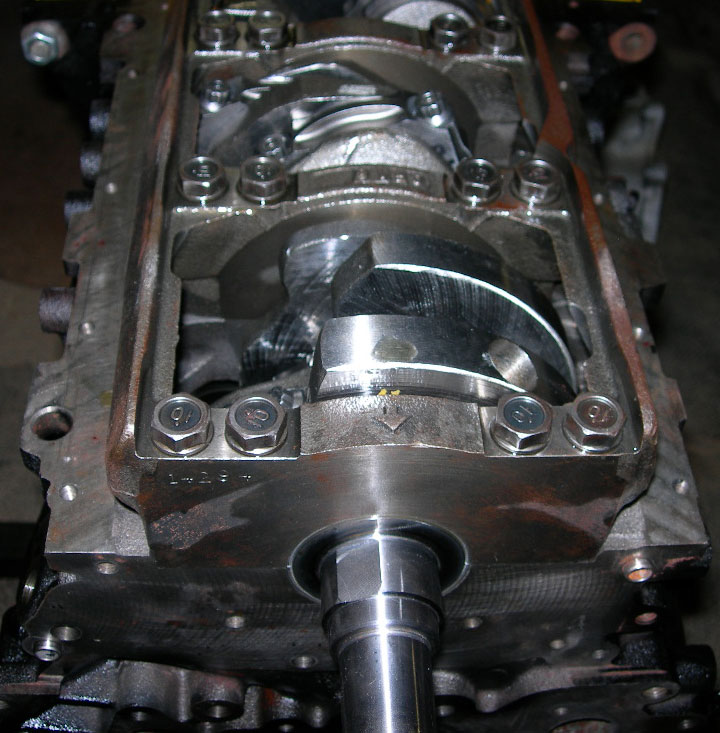

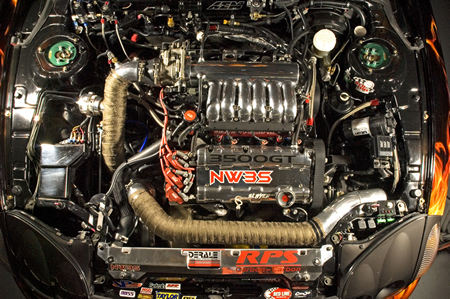

The block and crank are designed as a "stroker", meaning the stroke has been increased. So with the increased stroke and bore the 6G72 now has a 3.5L displacement. For rod, main, and thrust we use Clevite coated bearings sets. Motor mounts are solid steel mounts made strictly for racing. We use Redline brand 30 weight racing oil in the engine. |

Cylinder Heads are "Stage III" meaning they are setup just for racing. The heads are "O-ringed" to prevent head lift from high boost pressures. Some people ring the block, others the heads. We use OEM multi-layer steel head gaskets applied dry and head studs torqued to 100 ft/lbs. The heads on the 6G72 are aluminum. The heads intake and exhaust are ported and polished. To work with these heads our upper and lower intakes are also both professionally ported and gasket matched. Intake valves are stainless steel black nitride (SSBN) and are +1mm size (36mm). The exhaust valves are also stainless steel black nitrided valves and are +2mm sized (32.5mm). Valve spring retainers are titanium. Another popular racing valve option these days are the inconel valves. Inconel or SSBN valves are important for the extreme heat they are subjected to. Valves springs are "hi-rev option" meaning they are double springs with titanium retainers and lower locators. |

|

Camshafts are hardweld racing cams with .4 inch lift. Onto these we use UR adjustable camshaft gears, polished. We currently keep the gears at 0/0 degrees on these cams and with fuel used. Lifters are hydraulic (OEM) and rockers are roller style (OEM). |

|

Note: for timing components we use airtext and OEM. For timing belt we use a standard belt (PCI or Gates) and change it each year rather than use a 'kevlar' style belt. We still use the hydraulic style tensioner and use either OEM or ITM. |

|

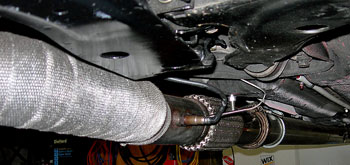

Exhaust manifolds and crossover piping to turbo base are custom made stainless steel and performance coated with titanium ceramic heat coating.

The 4" downpipe is all wrapped in the DEI titanium heatwrap. |

The exhaust from the turbo is a 4" stainless steel downpipe and straight 4" stainless steel to rear of car with 5" termination. |

On the left is the stock throttle body. On the right is the 90mm throttle body we use. This allows for a LOT more flow. Using this system we also have no TB coolant lines or any idle air controllers at all. Idle is achieved via the AEM EMS system and therefore there is no need for those in our application.

|

To accomodate the 90mm throttle body addition we have a non-standard intake manifold that has been made for this and then highly polished. This intake is also shorter to allow for changing rear spark plugs without removing the plenum. The lower intake (not shown) is also ported and polished and gasket matched.

To the right you see the 4" intercooler piping terminating at the 90mm throttle body. |

|

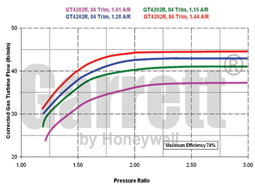

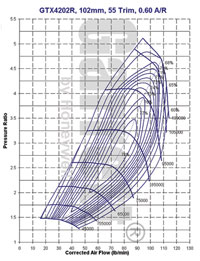

The turbo used in this application is a Garrett GTX4202R. It has billet compressor and is a ball-bearing turbocharger. It is oil and water cooled. We also use a DEI titanium turbo thermal blanket (not shown) on the hot side.

The turbo fresh air intake is a full 5" and located down low for good intake of outside air. We use a K&N 5" inlet air filter. |

Compressor map and other turbo information charts.

|

The single turbo conversion parts, stainless steel and ceramic titanium coated. Showing the exhaust headers, crossovers and turbo base. Also shown in the above photo are the two tial wastegates.

For the wastegates we use TIAL 44mm stainless steel premium wastegates and setup with internals for leaded fuels.

|

The Blow Off Valve (BOV) is a Tial and is 50mm in size.

|

Due to the location of the turbo we use a Scavenge pump system. This consists of a custom tank we fabricated for drainage and anti-foam drainage into a Turbowerx brand 12v oil pump via a -12AM line then back into the oil pan via a -10AN line. The FMIC (Front Mount Intercooler) uses 3" aluminum piping and is also polished. Over this we use more of the DEI titanium heat wrap. For additional intake temperature cooling we use a DEI cryo system that floods the intercooler with liquid CO2 (carbon dioxide) for a rapid cool down. Exact temperature changes can easily be monitored inside the cab. The CO2 has no affect whatsoever by being taken in at the intake from all of our testing on the dyno.

|

|

Front Intercooler and showing the CO2 manifold

|

Solenoid for the liquid CO2 control is |

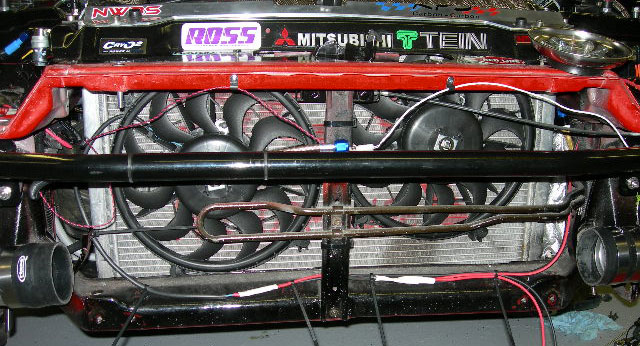

COOLING With this much power it is critical to have a very efficient and effective cooling system. Our system can maintain optimum operating temperatures at all phases included back to back all-out 1/4 mile runs and constant dyno WOT runs. We have never overheated. We use a dual pass aluminum radiator, no thermostat, and deionized distilled water with 1 bottle of Redline waterwetter. We use a Setrab 920 oil cooler with twin fan packs (inside look at the install on the right). The fans come on automatically once oil temperature reaches 205 degrees F. In addition to this there is also a Fuel cooler in the trunk. Also a Setrab and includes a fan pack (more in the "fuel" section of this website section). This helps to keep the fuel cooled and is in the return path to the fuel cell. |

|

Radiator Fans

We use two high output Derale cooling fans at the radiator. These are pusher style and push air through the radiator rather than pull. The main fan maintains 190-205 degrees F and the 2nd fan quickly brings temps down under 205 should it be needed. Fans are shut down once speed exceeds 60mph. These fans each require 30 Amp breakers so they have thier own specific power buss.

All fan systems (radiator 1 & 2, oil cooler, fuel cooler) are automatic with the ability to over-ride inside the cabin when desired. Automated control is accomplished via the AEM engine management system. |

Bumper off and intercooler out showing the radiator fan install and the

tube crash bar installed.

Ignition coil system on engine. Wiring goes into the cabin where the electronic controller is located (out of the heat of the engine bay). The majority of the ignition control however is turned over to the AEM Engine management System (see electronics). |

IGNITION SYSTEM

MSD ignition throughout. With a DIS-4 electronic ignition system that controls 3 GM style high output coilpacks. Spark blowout is not an issue.

|

Spark Plug wires - magnecore 10mm Spark Plugs - NGK R5671A-8

|

Preoiler system For startup engine protection a preoiler system is used. It is mounted just forward of the power steering resevoir. A tilton electric cooler pump takes filtered oil from the oil pan and distributes it through the oiling system at approximately 20psi via -6AN lines. Any time the engine has sat for more than a day we use the preoiler system prior to starting the car. This makes sure that all the critical components are oiled and ready for startup. |

|

Engine Control Just about all engine control is via the AEM engine management system (ECU). See details in the electronics page.

|

A/F O2 Monitoring We utilize two wideband O2 systems to monitor the engine Air/Fuel ratio during tuning and other non-race functions. All systems are AEM. We do not allow the wideband to compensate the fuel map at any time but instead it is for monitoring conditionsas needed. We also repalce the sensors each year due to the wear that leaded fuel has on O2 sensors. |

Water/Alcohol Injection We have a complete AEM water injection system installed in the car. At this time we do not turn it on as the fuel we are using currently keeps our charge temperatures where they need to be. In the future we may engage the system and experiment with it and/or other fuels. Seen above : custom in-house water injection control and monitoring panel and voltage monitoring panel. |

|

Completed engine on stand and in the car. See the photos menu for specific photos of the engine and installation. |

|

Note on branding or specific company parts and/or service: We specifically do not go into detail on brands or vendors unless it is relevant to the build specs or if the vendor has provided reciprocal links and mention on their website(s) or other venues. Companies that have provided consideration through their sponsoring program are mentioned by name and or link(s). We are glad to reciprocate where applicable, especially on custom work (just email and ask us if you see something missing). Or, if multiple generic choices exist we may mention brand or vendor. |

Back to Build Menu

(for more details on fuel, ectronics and other car specifications)

Go to Engine Photos section

(complete photos of completed engine and install)

|

|