|

|

||||||||||||||||

|

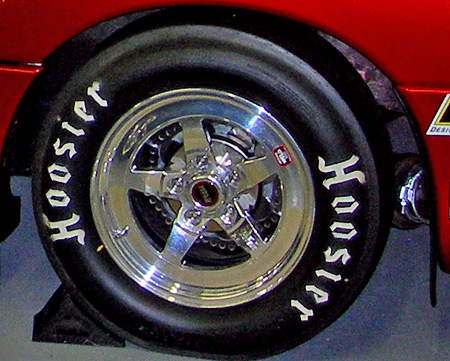

TIRES

An extremely important aspect of drag racing is of course the tires. Being able to gain traction upon launching at the starting line. Racing slicks are made just for this purpose. In addition the sidewalls flex a great deal at launch thereby absorbing some of the immediate forces which helps prevent breakage of parts of the driveline system, Very important in high horsepower applications! So enough traction to put down the power you have at the line and still not break loose from the pavement. In this endevour the tire combination and considerations are very critical to the goal (fastest time). Full racing slicks, also known by some as 'cheater slicks' do not come in the sizes the 3000GT is designed for (17 and 18 inch). The best you can do in those sizes is drag racing radials which are not even close to what a real drag slick does. To get into the true racing slick the wheels have to be smaller. Then we can get the racing slicks on there.

|

|

|

Since the 3000GT is an all-wheel-drive (AWD) we have the same size slicks in front as in back for traction. Although having wide tires in front make steering more difficult at high speeds it is necessary to prevent wheel spin with the tire losing traction if not enough surface area when launching the car. Currently shown on the left are 26x8.5 Hoosier drag racing slicks. |

BRAKES

|

The wheels on the NW3S 3000GT VR4 are made by Weld Racing. They are extremely lightweight (as in 14 lbs ea!) and are forged aluminum construction.

This lightweight plus the lightness of the slicks means a severe reduction in rotational weight. Removal of rotational mass or weight is a big goal in drag racing. In addition you can see the lugnuts used for NHRA compliance (i.e.-upon inspection for wheel stud length and thread count) with the open end. |

|

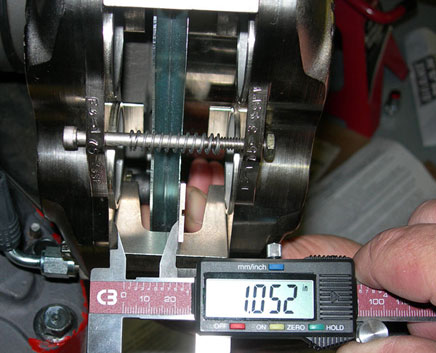

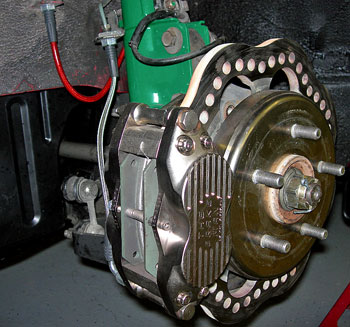

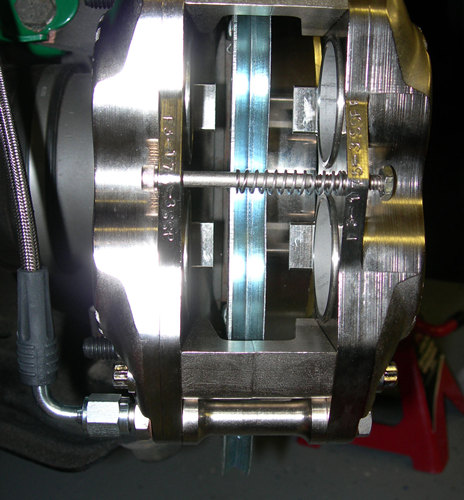

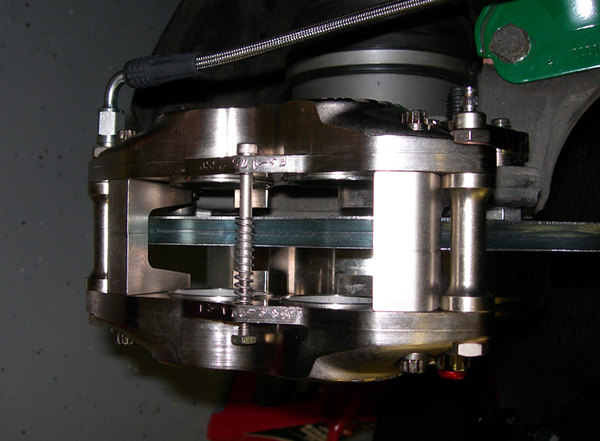

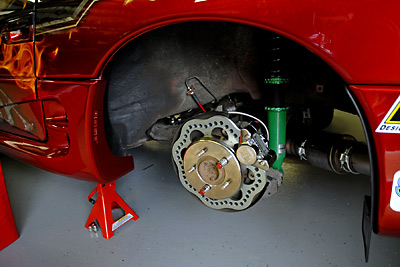

OK, so now that we have 15" wheels that will fit the 3000GT and drag slicks mounted what about the brakes? Because these wheels will not fit over the big brakes that the 3000GT VR4 comes with. So smaller profile brakes are needed and ones that can withstand extreme conditions and stop the car from very high speeds and in a short distance. While there are a few performance brake systems for the 3000GT on the market very few met what our needs were (performance, zero-drag / full release style, etc). We settled on the best we could find which is, in our opinion, Brakeman. Yes they are expensive (around $4000 for the calipers and rotors) but they are a critical component for obvious reasons. Brakeman has proven in many top drag racing cars for years to be top quality and reliability. We worked woth the Brakeman Company to get the materials produced for the 3000GT as no one had installed them before. So after trial and error plus numerous back and forth adjustments, measurements and fabrication a Brakeman Kit for the 3000GT was made.

|

adapters for fitment of the brakeman calipers.

|

|

The Brakeman calipers and rotors are easy to spot due to their unique design. Super light-weight and only the highest quality aluminum and other alloys are used. We have tested these on the 3000GT on FIVE back to back runs from 0-140-0 and there was NO fading whatsoever. All of the stops were emergency stop style - hold to the floor to zero. These stopped the car way better than the bigger OEM brakes every time! They heated up hot enough to see them glow that night and then performed as expected minutes later on another stop from 140mph to zero. We have no doubt about the stopping ability of these brakes up to 200 MPH How about weight savings? ROTORS

That is some SERIOUS weight savings right there. The reduction in rotationla mass is tremendous and makes a measureable and noticeable difference in the cars performance. |

|

|

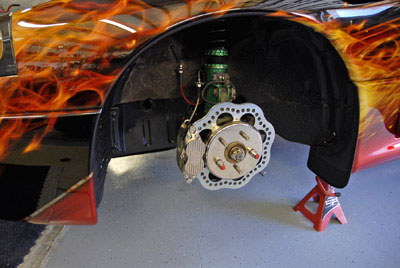

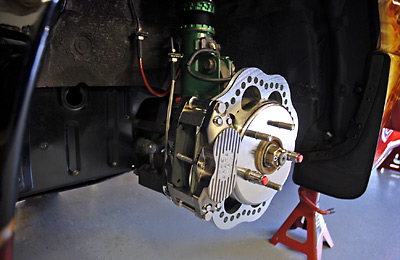

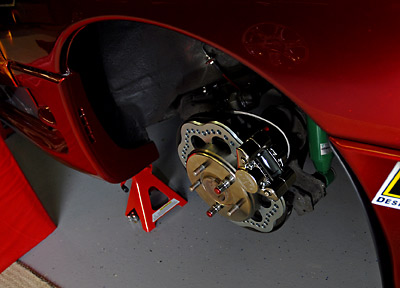

Here's the brakes all installed on the 3000GT VR4. - Front brakes on the left Rear brakes on the right -

|

|

Tires, wheels and brakes on the car |

|

|